Laminar Flow Systems

Laminar air flow systems for different requirements for personal protection, product protection or a combination of personal and product protection as standard or special designs.

Laminar air flow systems for different requirements for personal protection, product protection or a combination of personal and product protection as standard or special designs.

LAF systems offer product protection for different sized work areas, e.g. Sampling, general process technology and sterile filling of pharmaceutical and related applications.

Product protection is achieved through targeted air flow. An unidirectional air flow streams vertically into the work area of the cabin and escapes into the surrounding area near the ground – airborne particles are captured and removed in a controlled manner.

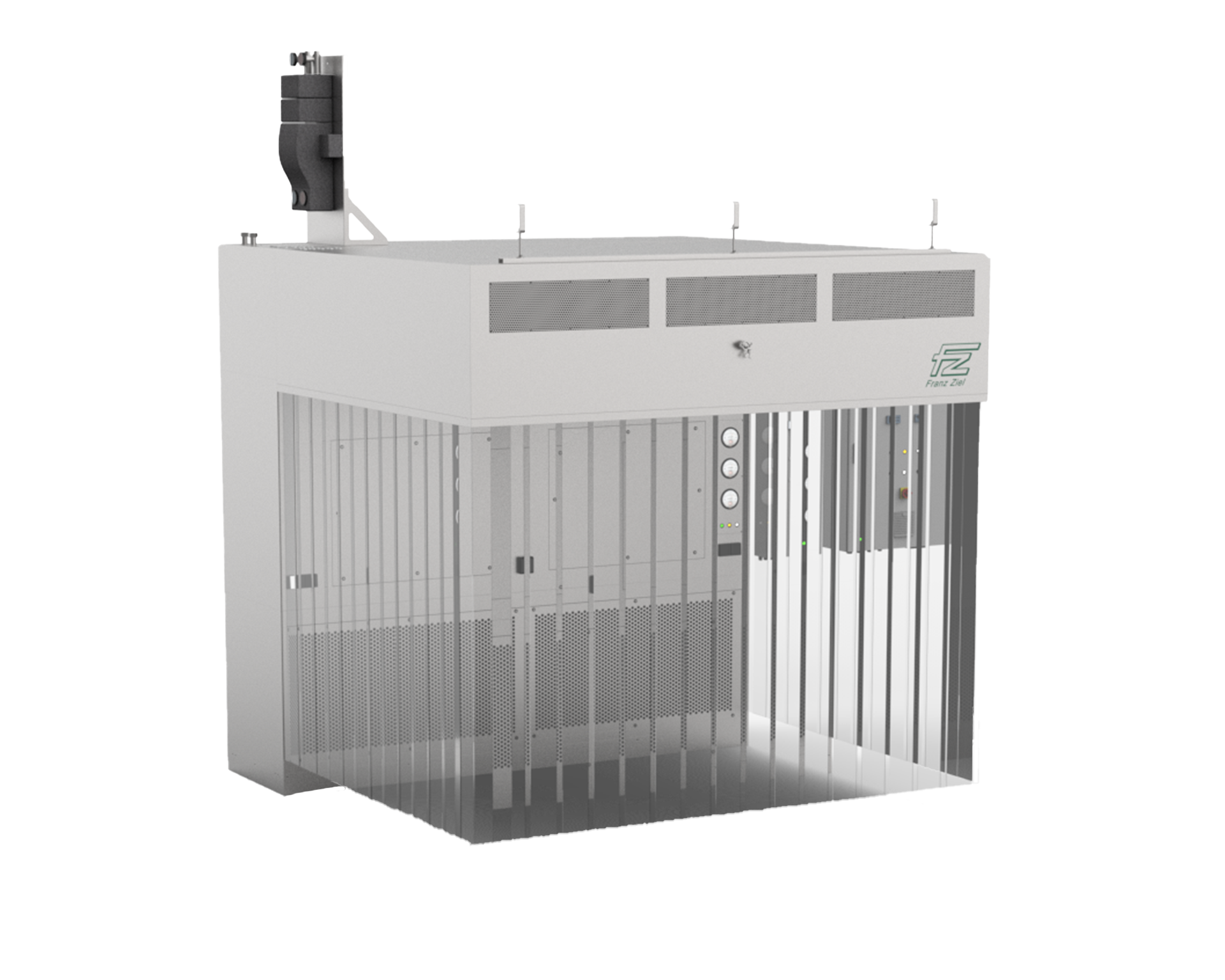

LAF downflow booth offer product and personal protection when weighing or sampling powdered substances. These conditions are achieved through targeted air circulation.

An unidirectional air flow streams vertically into the work area of the downflow booth and is extracted near the floor – air-borne substances are recorded in a controlled manner

The integrated exhaust system, which creates a slight negative pressure in the work area of the downflow booth, permanently protects the surrounding area from contamination. A connection of the air recirculation cabin to an on-site supply or exhaust air system is not necessary.

LAF work benches provide high levels of air cleanliness via HEPA filtered uni-directional air flow (UDAF) for laboratory scale work processes.

Applications include filling of technical batches in bench top filler – capper modules where products require protection from airborne particulate contamination and environmental monitoring is applied based on risk assessment.

When GMP clinical or small batch filling is required other products based on barrier technology (Isolators and RABS) are also part of the product portfolio.